A specific designation within the electric motor sector, known as the Y3 motor, is attracting focused interest from manufacturers and engineers involved in precision-driven industries. This category of motor, defined by a particular set of performance specifications and design standards, is being recognized for its potential in applications requiring a balance of compact size, efficient operation, and reliable torque delivery. The exploration of Y3 motor technology highlights a trend toward the customization and optimization of motor platforms for well-defined operational roles.

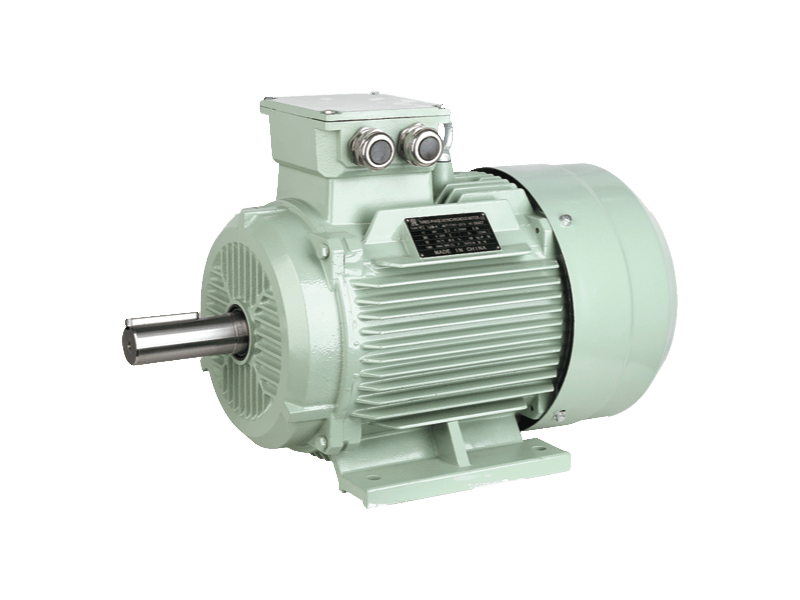

The Y3 motor typically refers to a three-phase asynchronous motor design built to conform to certain efficiency and dimensional benchmarks. Like many industrial motors, the core function of a Y3 motor is to convert electrical energy into rotational mechanical force. However, the engineering focus for a Y3 motor often emphasizes achieving a favorable power-to-size ratio and meeting specific international efficiency classification standards. This makes the Y3 motor a considered choice for system integrators where space constraints and energy consumption are important factors in equipment design. The internal construction of a Y3 motor, including its stator winding configuration and rotor design, is optimized to reduce electrical losses and manage thermal performance effectively.

The application landscape for the Y3 motor is diverse, spanning several equipment categories. A common use for a Y3 motor is within various types of machinery, including small pumps, fans, compressors, and conveyor systems. In these applications, the dependable and consistent output of a Y3 motor supports continuous operation. Furthermore, the Y3 motor is often selected for integration into specialized industrial tools, textile machinery, and food processing equipment where its standardized footprint and performance characteristics simplify the design and sourcing process for original equipment manufacturers. The suitability of a Y3 motor for these roles is frequently based on its ability to provide reliable service without requiring highly specialized control systems.

From a technical development perspective, the evolution of the Y3 motor parallels broader trends in motor manufacturing. Advances in materials, such as the use of higher-grade electrical steel for the core and improved insulation for windings, contribute to the enhanced efficiency and longevity of a modern Y3 motor. Manufacturing processes are also refined to ensure precise tolerances and consistent quality in the production of the Y3 motor, which is crucial for its performance in assembled systems. These incremental improvements ensure that the Y3 motor remains a competitive and relevant component in its target market segments.

The adoption of the Y3 motor is also influenced by global emphasis on energy efficiency in industrial equipment. Regulations and voluntary standards that encourage or mandate the use of higher-efficiency motors in commercial and industrial products create a favorable environment for motor designs like the Y3 motor that meet these criteria. For end-users, selecting a system powered by a Y3 motor can contribute to lower long-term operational costs through reduced electricity consumption, aligning with both economic and sustainability goals.

The role of the Y3 motor is expected to remain stable within its established applications. Future iterations may see further optimization for noise reduction, integration with plug-and-play variable speed drives, and perhaps the incorporation of smart sensor technology for basic condition monitoring. Its continued presence underscores the demand for proven motor solutions that deliver specific performance within defined parameters, supporting the reliable function of countless machines that form the operational layer of light and medium industry worldwide.