In the expansive world of industrial automation, manufacturing, and commercial infrastructure, a ubiquitous class of electric motors provides the foundational force for countless applications: the low voltage motor. Typically defined as motors designed to operate on voltages below 1000V AC, these units are the common drivers for pumps, fans, compressors, conveyors, and machine tools. The widespread use of low voltage motor technology is rooted in its balance of performance, safety, efficiency, and ease of integration, making it an indispensable component in systems ranging from factory floors to building management.

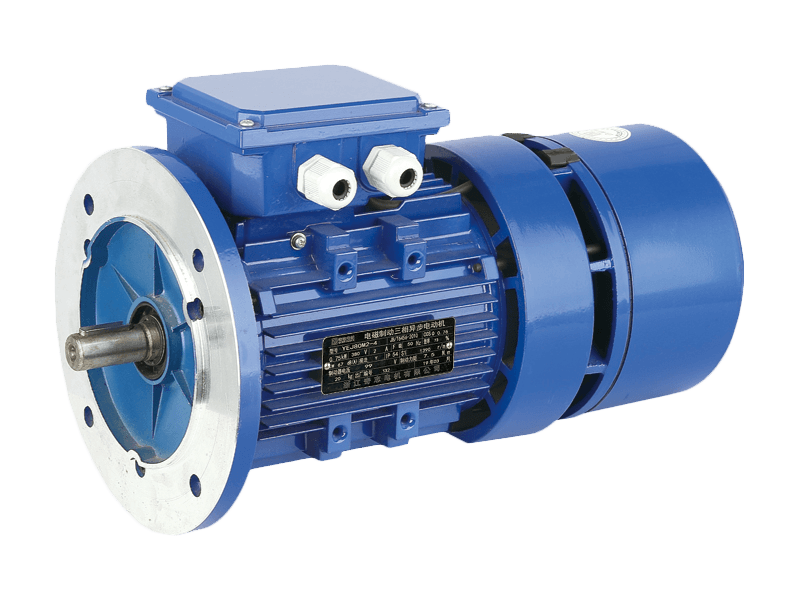

The defining characteristic of a low voltage motor is its operating voltage range, which commonly includes standard three-phase supplies like 400V, 480V, or 690V, and single-phase supplies such as 230V. This voltage classification aligns with readily available electrical distribution systems in industrial and commercial facilities, eliminating the need for complex and costly step-down transformers at the point of use. The design of a low voltage motor prioritizes robust construction to deliver reliable mechanical power. Key components include a stator with windings optimized for the specific voltage, a rotor (often squirrel-cage for induction motors), durable bearings, and an efficient cooling system, often using an integrated fan.

A primary advantage of the low voltage motor is its contribution to operational safety and practicality. Working with lower voltages inherently reduces certain electrical hazards compared to medium or high-voltage systems, simplifying installation, maintenance, and repair procedures. This allows for more straightforward connection methods, commonly using terminal boxes, and facilitates the use of standard motor control components like contactors and variable frequency drives. The manageable size and weight of many low voltage motor models also support easier handling and mounting within machinery and plant layouts.

The application spectrum for the low voltage motor is exceptionally broad. In industrial manufacturing, these motors are the driving force behind production lines, powering everything from packaging machinery and robotic cells to mixers and presses. Within commercial and residential buildings, low voltage motor units are integral to HVAC systems, driving fans in air handlers, pumps for chilled and hot water circulation, and compressors in refrigeration units. They are also fundamental in water and wastewater treatment plants, agricultural irrigation systems, and material handling logistics. The versatility of the low voltage motor lies in its availability across a wide range of power ratings, from fractional horsepower units for small devices to several-hundred-kilowatt models for heavy-duty industrial applications.

Innovation in low voltage motor technology continues to focus on greater efficiency, integration with digital systems, and enhanced durability. Trends include the wider adoption of permanent magnet synchronous motor designs within the low voltage range for their predominant efficiency and power density. The integration of sensors for condition monitoring—measuring temperature, vibration, and electrical parameters—is turning the low voltage motor into a smart component within the Industrial Internet of Things, enabling predictive maintenance and optimized system performance. As industries worldwide strive for smarter, more efficient, and more sustainable operations, the low voltage motor will remain a central, evolving technology, continuously adapting to deliver reliable motion as the fundamental driver of the modern mechanized world.