From the gentle breeze of a desk fan to the powerful airflow in industrial ventilation, a single component serves as the universal heart of the system: the fan motor. This specialized electric motor is engineered with one primary purpose: to convert electrical energy into the reliable rotational motion needed to spin fan blades or impellers. The ubiquitous fan motor is a testament to applied electro-mechanical design, found in an astonishing array of applications that regulate temperature, ensure safety, provide comfort, and support industrial processes across the globe.

The core function of any fan motor is to deliver consistent torque at a speed suitable for moving air. While the basic principle is simple, the execution varies widely. In small appliances, a shaded-pole or permanent split-capacitor fan motor offers a cost-effective and reliable solution. For applications demanding more power, variable speed, or precise control, such as in computer cooling or modern HVAC systems, brushless DC fan motor technology has become prevalent. These motors use electronic commutation for greater efficiency, longer life, and the ability to adjust speed smoothly in response to thermal or control signals. Regardless of type, the fan motor must be designed to operate continuously for extended periods, often with small maintenance, making reliability a paramount concern.

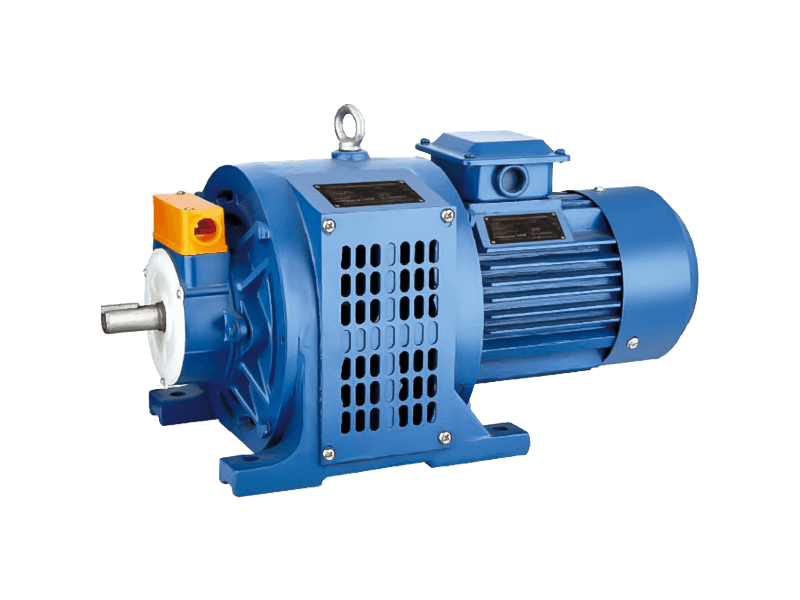

The application of the fan motor spans virtually every sector of modern life. In the domestic sphere, it is inside ceiling fans, exhaust fans, portable fans, and kitchen range hoods. In computing and electronics, miniature fan motor units provide critical cooling for components in servers, laptops, gaming consoles, and power supplies. The automotive industry relies on fan motor units for engine cooling and cabin climate control. On a larger scale, industrial fan motor drives are the powerhouse for commercial HVAC air handlers, warehouse ventilation, fume extraction systems, and cooling towers. In each context, the fan motor is selected for its specific performance requirements: airflow volume (CFM), static pressure capability, noise level, power consumption, and physical size.

Design and material considerations for a fan motor directly influence its performance and longevity. Bearings are a critical focus; sleeve bearings are common in cost-sensitive, low-noise applications, while ball bearings offer greater durability for heavier loads or continuous operation in harsh environments. The motor's housing must facilitate effective heat dissipation. For brushless DC fan motor models, integrated control electronics manage speed and monitor performance. Furthermore, ingress protection ratings are specified for motors used in dusty, humid, or washdown conditions, such as in commercial kitchens or agricultural settings. These design choices ensure the fan motor can meet the demands of its specific operating environment.

The evolution of the fan motor is intertwined with trends toward smart connectivity, enhanced materials, and even greater efficiency. Future developments may include wider integration of IoT sensors within the fan motor housing to provide real-time data on performance, health, and energy use for predictive maintenance systems. Advances in magnetic materials and motor topology could yield smaller, more powerful, and even quieter fan motor designs. As the need for thermal management grows in everything from data centers to electric vehicles, and as comfort and air quality remain priorities, the humble fan motor will continue to evolve, quietly ensuring the vital flow of air that supports our technologies, our environments, and our well-being.