When a three phase motor has to run twenty-four hours a day for years, small details in design and workmanship decide whether you enjoy steady output or spend weekends chasing breakdowns. Knowing how to recognise those details before you buy is therefore the cheap form of maintenance a plant or farm can practise.

Begin with the nameplate data. A quality motor lists full-load efficiency and power factor to two decimals, not rounded figures; it also quotes IEC or NEMA frame size, insulation class, and duty cycle. If the plate omits temperature rise or lists “S1” duty without a figure, ask why: reputable makers have nothing to hide.

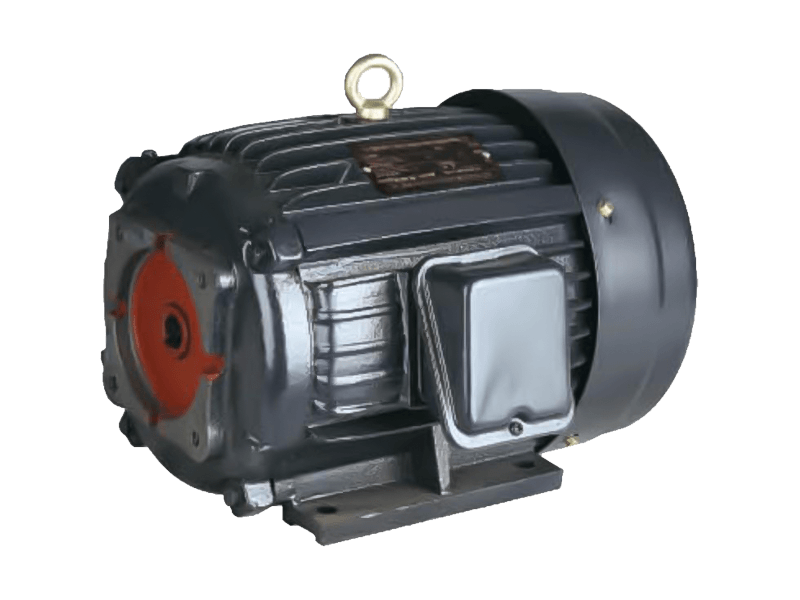

Next, weigh the motor. Two identically rated motors can differ by fifteen percent in mass; the heavier one almost always contains more copper and thicker stator laminations. Hold a magnet to the frame—if it sticks strongly all around, the housing is cast iron, which damps vibration better than the aluminium shells used in bargain units. Cast iron also survives accidental forklift bumps that would crack lightweight housings.

Open the terminal box. good models provide plated brass terminals with rubber gaskets, clearly numbered and separated by insulating barriers. Cheap versions use mild-steel hardware that rusts and encourages shorts. Look for a metal cable gland, not a plastic knock-out; the gland grips armour and keeps water out.

Study the bearings. A quality motor specifies SKF, FAG or NSK bearings on the nameplate and embosses the bearing code on the drive-end shield. Pull the fan cover and spin the shaft by hand—good bearings glide silently for several revolutions; roughness or end-play signals poor assembly. Sealed-for-life bearings cost more up front but eliminate regreasing errors that destroy windings.

Examine the fan. A backward-curved centrifugal fan made of glass-filled nylon moves more air with less noise than the straight-blade metal fans found in budget lines. A quality motor also mounts the fan inside a smooth shroud; uneven gaps indicate sloppy die-casting and will whistle at high speed.

Peer through the drain holes. They should be at the six o’clock position, threaded and supplied with stainless plugs. If the holes are smooth plastic or located on the side, condensation will sit in the frame and rot laminations. While you are underneath, look for a zinc passivation layer on the feet; dull grey paint over raw steel rusts within months.

Check certification stickers. CE and UL marks are common, but look further for ISO 9001 on the factory, IEC 60034 on performance, and IP55 or better on enclosure. A motor that meets IEEE 841 petroleum-grade standards will shrug off chemicals and high humidity that destroy ordinary units.

Finally, ask for the test sheet. A quality maker supplies a no-load and full-load curve, vibration spectrum, and insulation resistance measured at 500 V DC. If the vendor cannot produce these, assume they were never taken.