The international industrial sector is increasingly unifying around a common technological framework, with the IEC motor emerging as a pivotal element in this harmonization. As a product manufactured to specifications established by the International Electrotechnical Commission, the IEC motor provides a universal benchmark for performance, dimensional compatibility, and operational reliability. This widespread adoption of the IEC motor standard reflects a strategic shift within global industries toward enhanced interoperability, simplified maintenance protocols, and more streamlined international supply chains, fundamentally changing how equipment is designed and serviced worldwide.

The core principle behind the IEC motor concept is rigorous standardization. This encompasses critical aspects such as mounting dimensions, shaft height, flange configurations, and terminal box positions. This meticulous standardization ensures that an IEC motor produced by one manufacturer can be directly replaced with a mechanically compatible IEC motor from another supplier without requiring modifications to the driven equipment or baseplate. For original equipment manufacturers, this dimensional predictability of the IEC motor platform simplifies machine design, reduces engineering costs, and guarantees a competitive global market for replacement drives, thereby mitigating procurement risks and ensuring long-term operational continuity for their customers.

Beyond physical dimensions, the performance characteristics of the IEC motor are also clearly defined by international classifications. Key parameters such as efficiency levels, categorized under International Efficiency (IE) classes, are standardized across the IEC motor product range. This allows operators to make informed purchasing decisions based on verified energy performance data. The modern high-efficiency IEC motor, designed to meet IE3 or IE4 standards, delivers significant reductions in energy consumption, pilot to lower operational costs and a smaller environmental footprint. This focus on efficiency makes the contemporary IEC motor a cornerstone of corporate sustainability initiatives and energy management strategies.

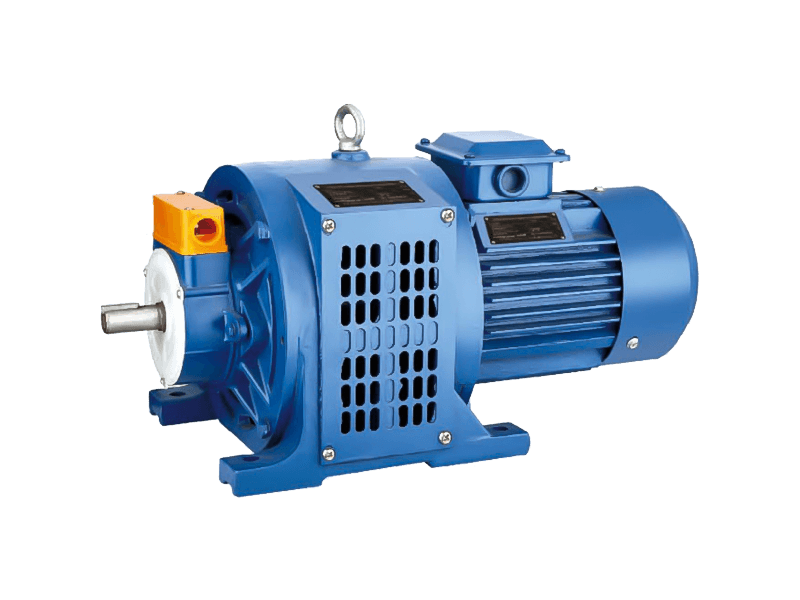

The universal application of the IEC motor across diverse sectors underscores its remarkable versatility. These motors are found powering vital systems in water and wastewater treatment plants, driving conveyor belts in sophisticated logistics hubs, and operating machinery in complex manufacturing facilities. The robust and reliable nature of the industrial-grade IEC motor makes it suitable for continuous duty cycles in challenging environments, from climate-controlled food processing plants to dusty mineral extraction sites. This broad applicability confirms the IEC motor as a truly globalized industrial component, capable of meeting a vast spectrum of power and torque requirements.

The benefits of the IEC motor standard extend powerfully into the realms of maintenance and asset management. The uniformity of the IEC motor design means that maintenance technicians can develop a transferable skill set; knowledge acquired while servicing one model of IEC motor is largely applicable to others. This reduces training overhead and improves troubleshooting efficiency.

The future development of the IEC motor is strategically aligned with the ongoing digitalization of industry. While preserving its standardized physical architecture, the next-generation IEC motor is increasingly being designed as an intelligent connected device. Modern iterations may incorporate sensors for condition monitoring, embedded thermal protection, and connectivity interfaces that allow the IEC motor to communicate operational data to broader control systems. This evolution positions the standardized IEC motor not just as a source of rotational force, but as a smart, data-generating node within the Industrial Internet of Things (IIoT) ecosystem, ready to meet the demands of increasingly automated and data-driven industrial operations for years to come.