As global industries shift toward sustainability and energy conservation, IE4 Three-Phase Asynchronous Induction Motors have emerged as key players in the transformation of energy-intensive operations. Recognized for their high efficiency, robust design, and adaptability, these motors are increasingly becoming the choice in modern industrial settings seeking to reduce their carbon footprint and enhance productivity.

High Efficiency Meets Global Standards

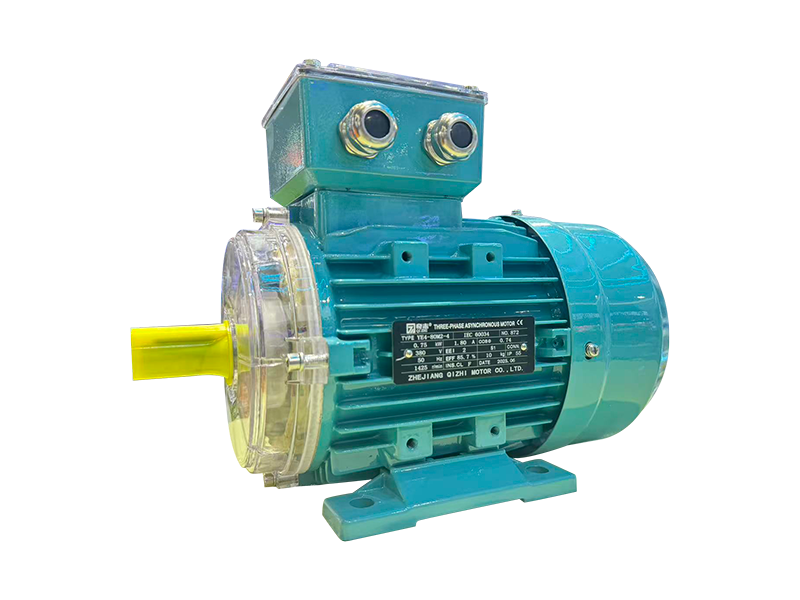

IE4 motors, such as the YE3/YX3 series, represent the next evolution of three-phase asynchronous induction motors. Engineered in accordance with international standards like IEC 34-1 and GB/T22722-2008, these motors offer energy efficiency that surpasses earlier Y series models. Often categorized as “efficiency” motors, they meet and exceed the IE4 efficiency class outlined by the International Electrotechnical Commission (IEC).

Thanks to their advanced electromagnetic design and manufacturing precision, these motors reduce energy consumption by up to 15% compared to conventional models, contributing significantly to long-term cost savings and lower environmental impact.

Versatility Across Industrial Applications

IE4 Three-Phase Asynchronous Induction Motors are designed for a broad spectrum of operating conditions. With ambient temperature tolerances ranging from -15°C to 40°C and a operating altitude of 1000 meters, they deliver reliable performance in diverse environments, from food processing plants to mining operations.

The motors are available in a wide voltage range (220V to 760V) and frequency options (50Hz and 60Hz), making them suitable for both domestic and international applications. Their IP55-rated protection ensures durability against dust and water, while insulation classes F and H provide resilience under thermal stress.

Features That Enhance Reliability and Safety

The YE3/YX3 motors stand out not just for their efficiency, but also for their engineering refinements. A sleek, modern housing design improves heat dissipation, while low vibration and noise levels enhance workplace safety and comfort.

The motors use the IC0141 cooling method and are built for continuous duty operation (S1), which ensures stable performance during long production cycles. Connection options include star-configuration for units up to 3kW and delta-configuration for 4kW and above, simplifying installation and integration with different power systems.

A Green Investment with Long-Term Gains

In a time when energy efficiency is not just a corporate goal but a regulatory requirement, investing in IE4 Three-Phase Asynchronous Induction Motors offers both compliance and commercial advantage. The reduced energy usage lowers operational expenses, while aligning with ESG (Environmental, Social, and Governance) goals for sustainability.

Manufacturers transitioning to IE4 motors can also benefit from government incentives and rebates in many countries promoting high-efficiency equipment, further reducing capital investment hurdles.

Looking Ahead: The Future of Motor Technology

The momentum behind IE4 motors is only expected to increase as more countries tighten energy regulations and industries look for smarter, greener technologies. The adaptability and high performance of the YE3/YX3 series make them a future-ready solution for sectors like petrochemicals, water treatment, metallurgy, HVAC, and heavy machinery.

As one industry analyst notes, “The adoption of IE4 motors is not just a technological upgrade—it's a strategic move toward a sustainable, high-performance future.”

For enterprises aiming to boost efficiency and environmental compliance, the shift to IE4 Three-Phase Asynchronous Induction Motors is no longer optional—it's essential.

About the Manufacturer

The YE3/YX3 series IE4 motors are produced by motor manufacturers committed to innovation and quality. With a focus on international standards, environmental responsibility, and customer satisfaction, they continue to set benchmarks in industrial motor development.